LinnOval® is another consistent addition to and further development of our product range, which we have been continually expanding since 1965.

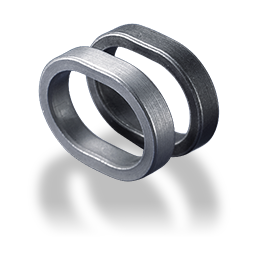

Through the precision manufacturing of turned, oval-shaped bushings, we are able to offer our customers solutions that provide tolerance compensation for complex plastic components.

Depending on customer needs, oval bushings are cold pressed, warm-implanted or injection-molded; we provide them with corresponding design recommendations. Thanks to this service of Linn Präzision, you benefit from the long-standing experience of our company in this area.

Our wide range of production capabilities also allows us to supply our customers with assembly parts right from the prototype stage.

Our manually operated inserting machines are capable of producing small-sized and medium-sized series cost-effectively, while large series in particular, which are produced by our fully automatic machines equipped with robots, round off our service profile cost-effectively.