Despite using the latest machines and consistently following the zero-defect strategy, a small number of reject parts are unavoidable when manufacturing fasteners.

For example, an error rate of approx. 0.1–0.5 percent is possible when producing turned work pieces under optimum conditions.

This is an excellent production result, but it is not good enough for many of our customers.

The number of reject parts also increases due to the refining process. Foreign bodies or parts that are unintentionally mixed between the products during the electroplating/hardening process reduce the efficiency of our customers’ production facilities because of machine breakdown.

Processed reject parts lead to costly complaints and negative performance evaluations from the end user.

Since 1991, we have been working towards finding a solution to this issue, which has resulted in the following for our customers:

- Reduction in error costs

- Increase in productivity

- Further processing with minimal errors

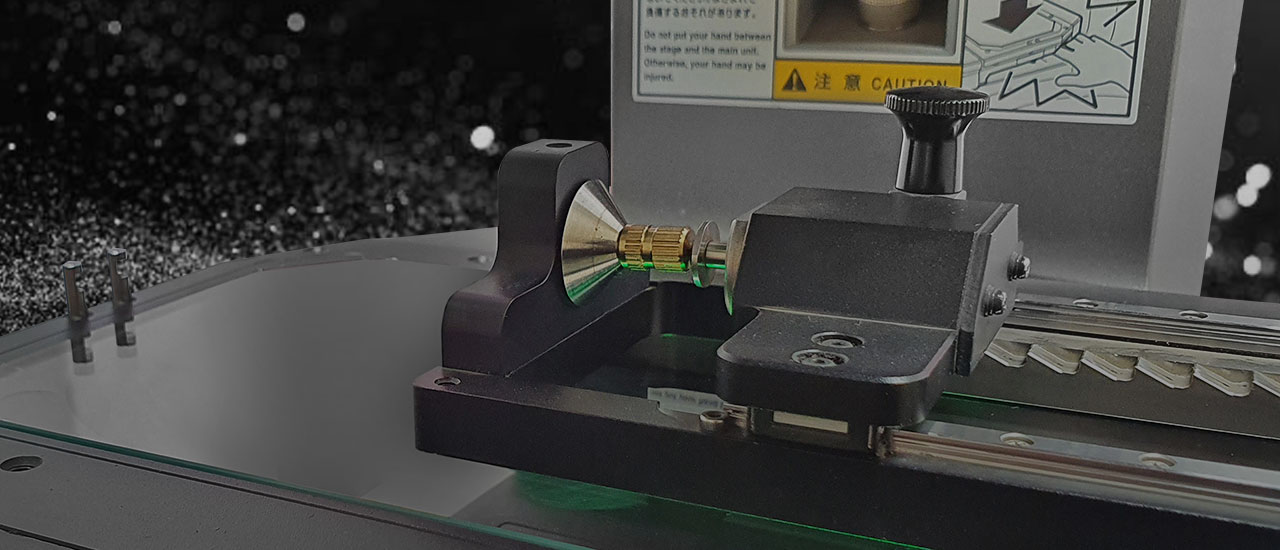

We use machines from a variety of industrial fields, including mechanics, opto-electronics, electro-pneumatics and camera technology, depending on the test task in question. We create special testing machines according to our customers’ individual requirements.

The new generation of machines now also enables a reverse partial view with the latest camera technology. As a result, smaller tolerances can be checked and previously problematic features such as chamfers and threads are clearly visible – and at a remarkable speed of up to three units per second...

...and we are continuing to develop this technology!