Threaded bushings (threaded sleeves, threaded inserts, insert nuts) are often required in the plastic and casting industries. We work according to our customers’ requirements and DIN 16903.

In many cases, our in-stock standard bushings that meet the DIN 16903 requirements can be used instead of individually constructed, expensive varieties. Our customers benefit from our large stock of various types and dimensions, in particular at the product-sampling stage.

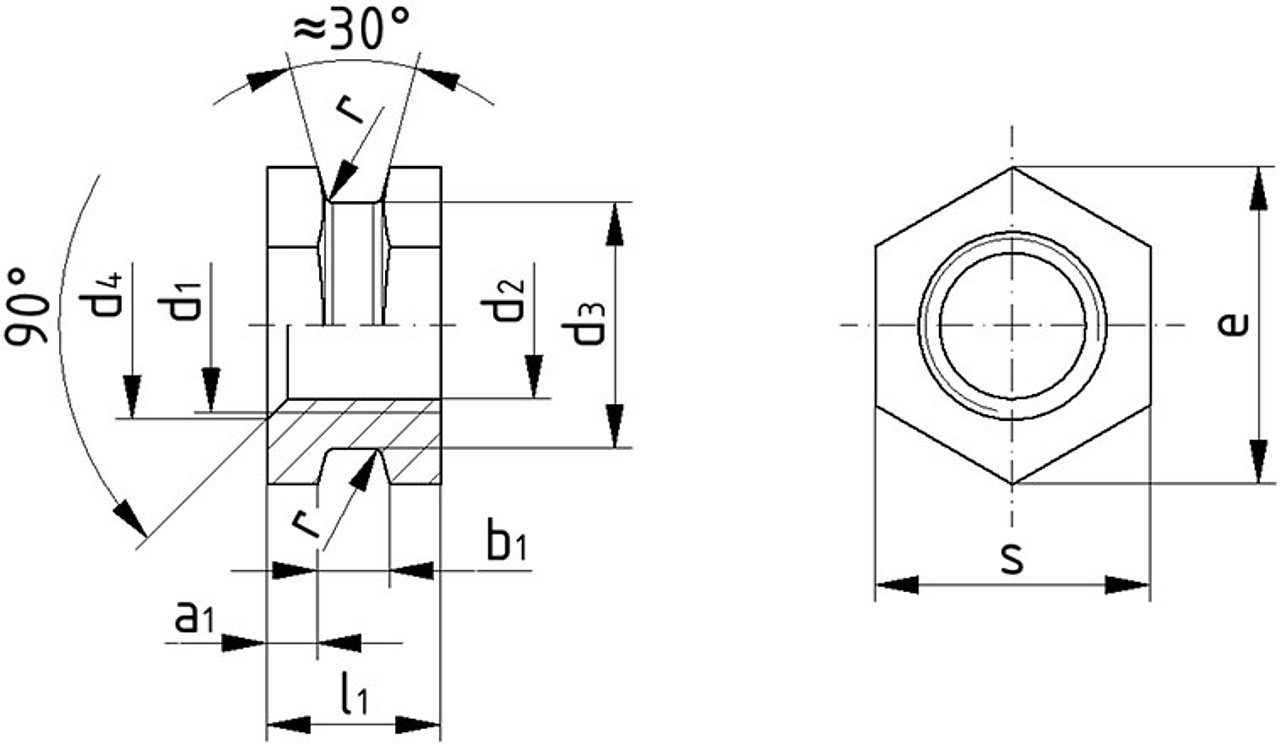

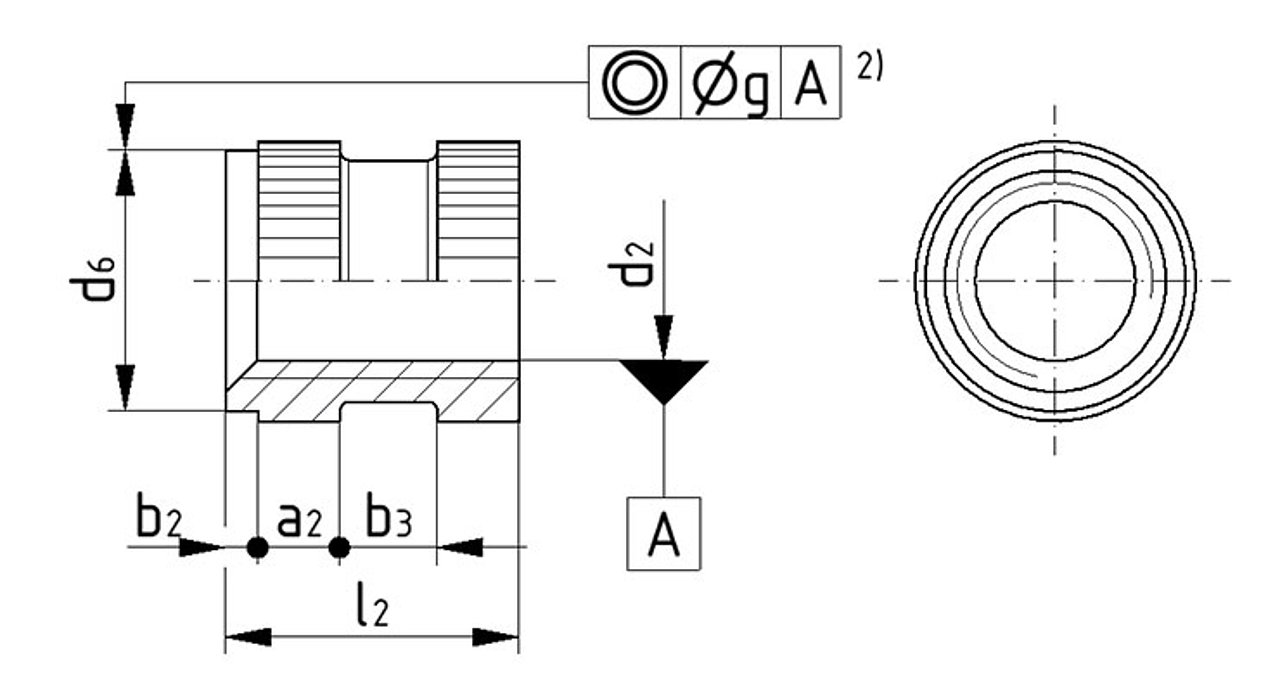

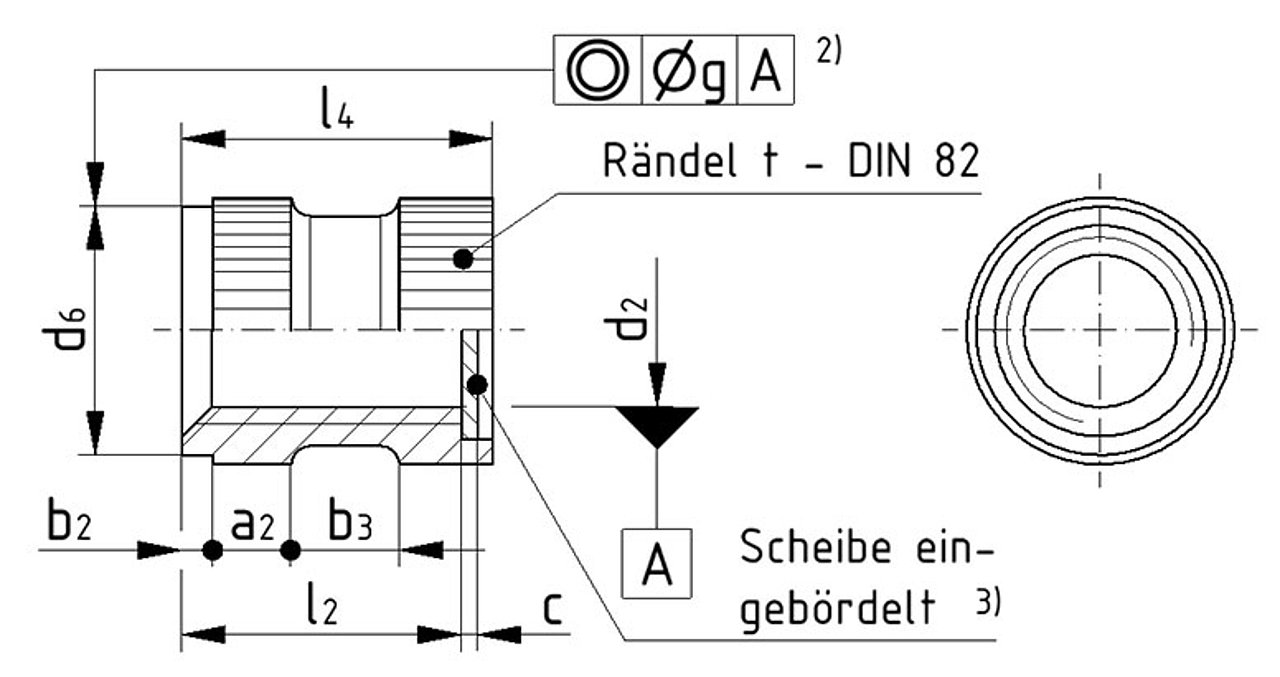

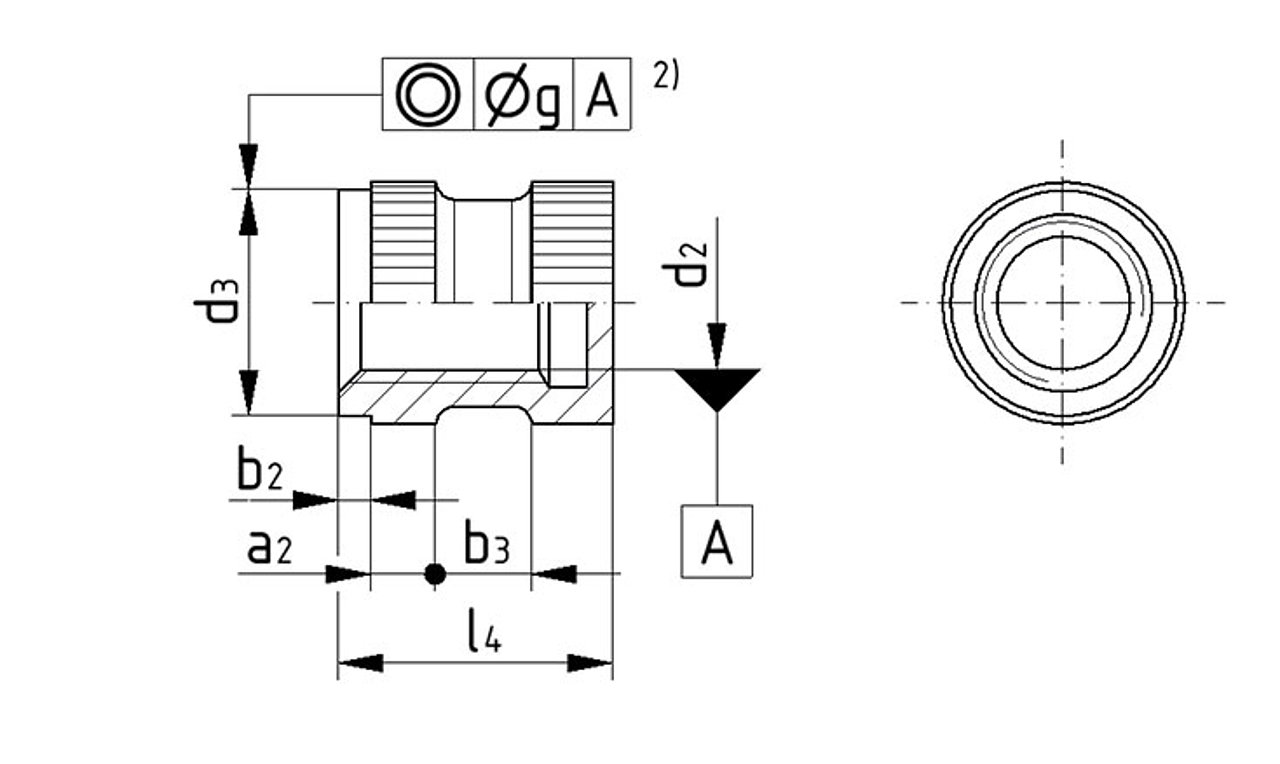

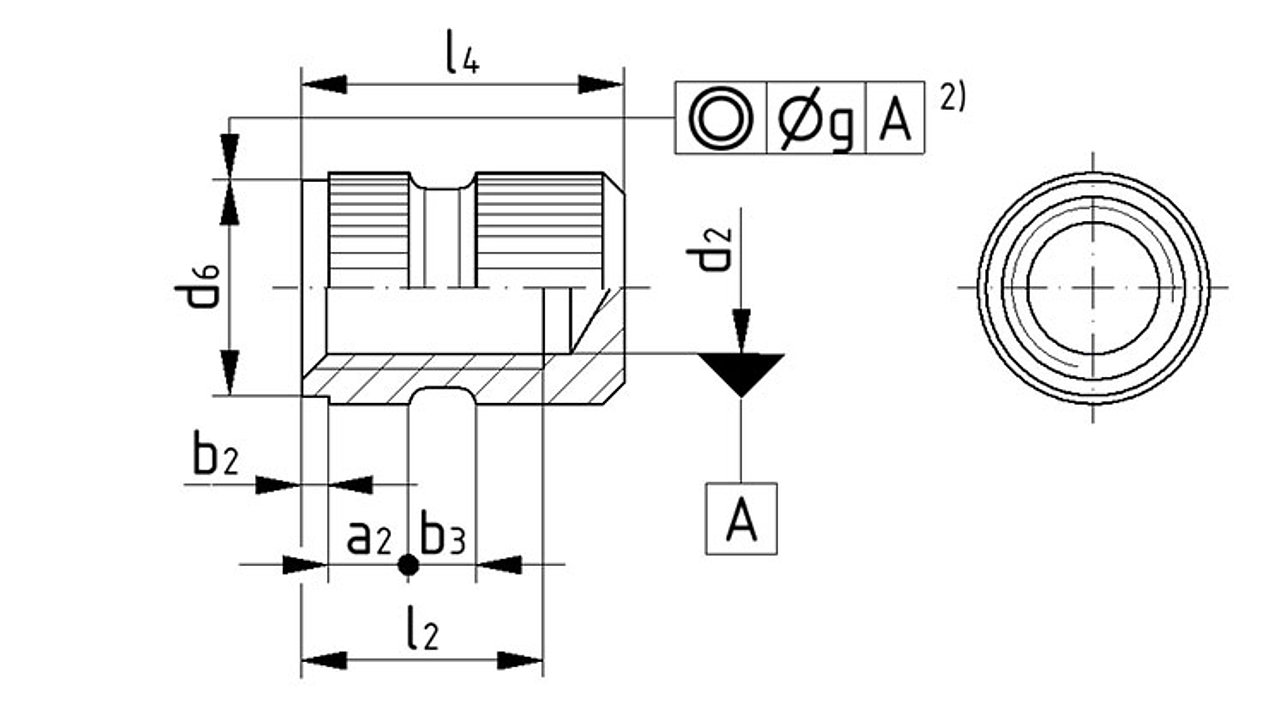

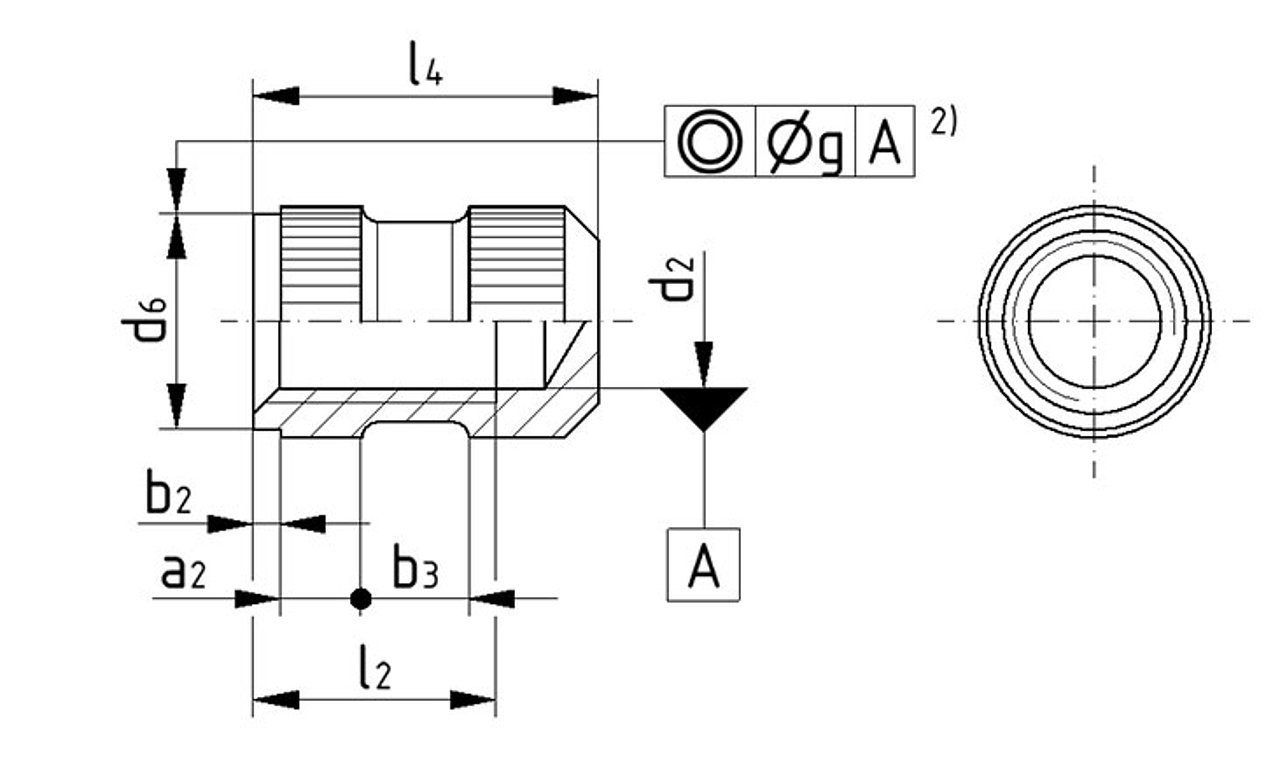

| Threaded bushings | |||||||||||

| Form | Tolerance | B / D | A / B / C / D | A / C | |||||||

| Thread d1 (6H) | M 2 | M 2.5 | M 3 | (M 3.5) | M 4 | M 5 | M 6 | M 8 | M 10 | M 12 | |

| a1 | 0.8 | 0.9 | 0.9 | 1 | 1.2 | 1.6 | 1.8 | 2 | 3 | 3.5 | |

| a2 | 0.9 | 1 | 1.2 | 1.6 | 1.8 | 2 | 2.5 | 4 | 4 | 5 | |

| b1 | 0.8 | 0.8 | 1.2 | 1.4 | 1.4 | 1.8 | 2.4 | 4 | 4 | 5 | |

| b2 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| b3 | 0.8 | 1 | 1.2 | 1.4 | 1.4 | 2.5 | 3 | 4 | 6 | 7 | |

| d2 | H11 | 1.6 | 2.05 | 2.5 | 2.9 | 3.3 | 4.2 | 5 | 6.8 | 8.5 | 10.3 |

| d3 | h12 | 3.2 | 3.4 | 3.8 | 4.5 | 5 | 6.4 | 7.4 | 10.4 | 13 | 17 |

| d4 | 2.7 | 3 | 3.4 | 4 | 4.5 | 5.5 | 6.8 | 8.8 | 11 | 13 | |

| d51) | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | - | - | - | |

| d6 | h11 | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | 10 | 12.5 | 16 |

| g | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.16 | 0.16 | 0.2 | 0.2 | |

| l1 | h12 | 2.3 | 2.6 | 3 | 3.5 | 4 | 5 | 6 | 8 | 10 | 12 |

| l2 | h12 | 3.5 | 4 | 4.5 | 5.5 | 6 | 7.5 | 9 | 12 | 15 | 18 |

| r | ≈ | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| t | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | 0.6 | - | - | - | |

| s | ≈ | - | - | 5 | 5.5 | 6 | 7 | 9 | 11 | 14 | 19 |

| e | ≈ | - | - | 5.8 | 6.1 | 6.9 | 8.1 | 10.4 | 12.7 | 16.2 | 21.9 |

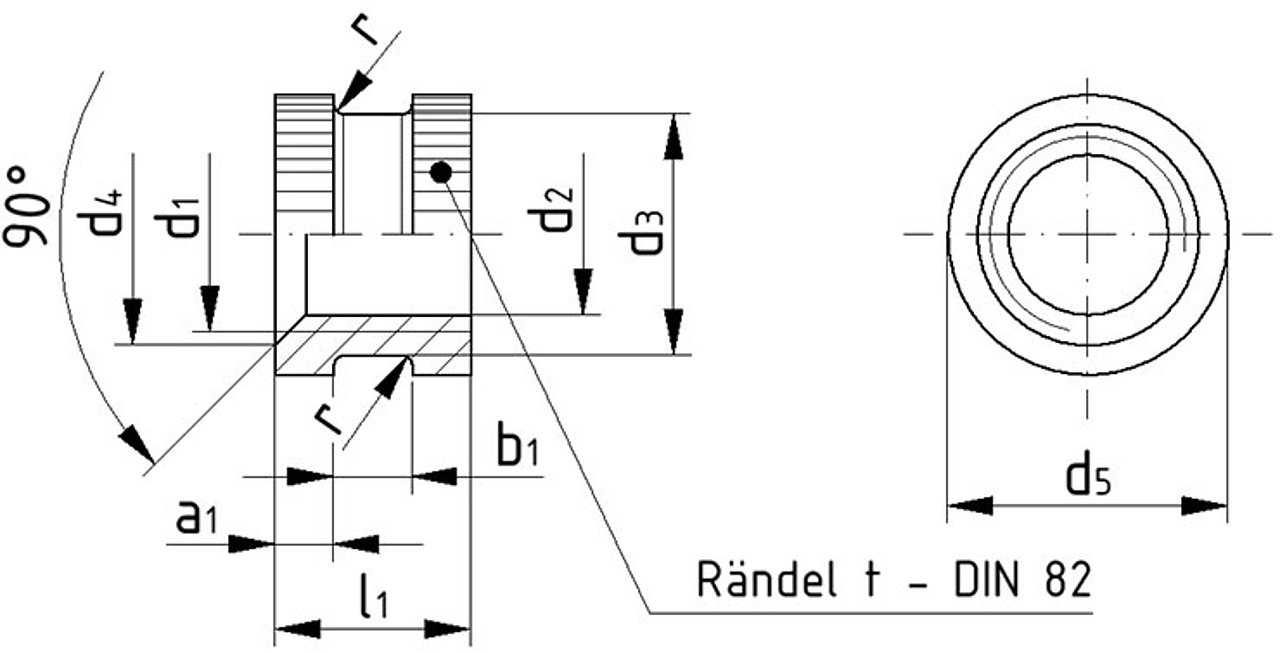

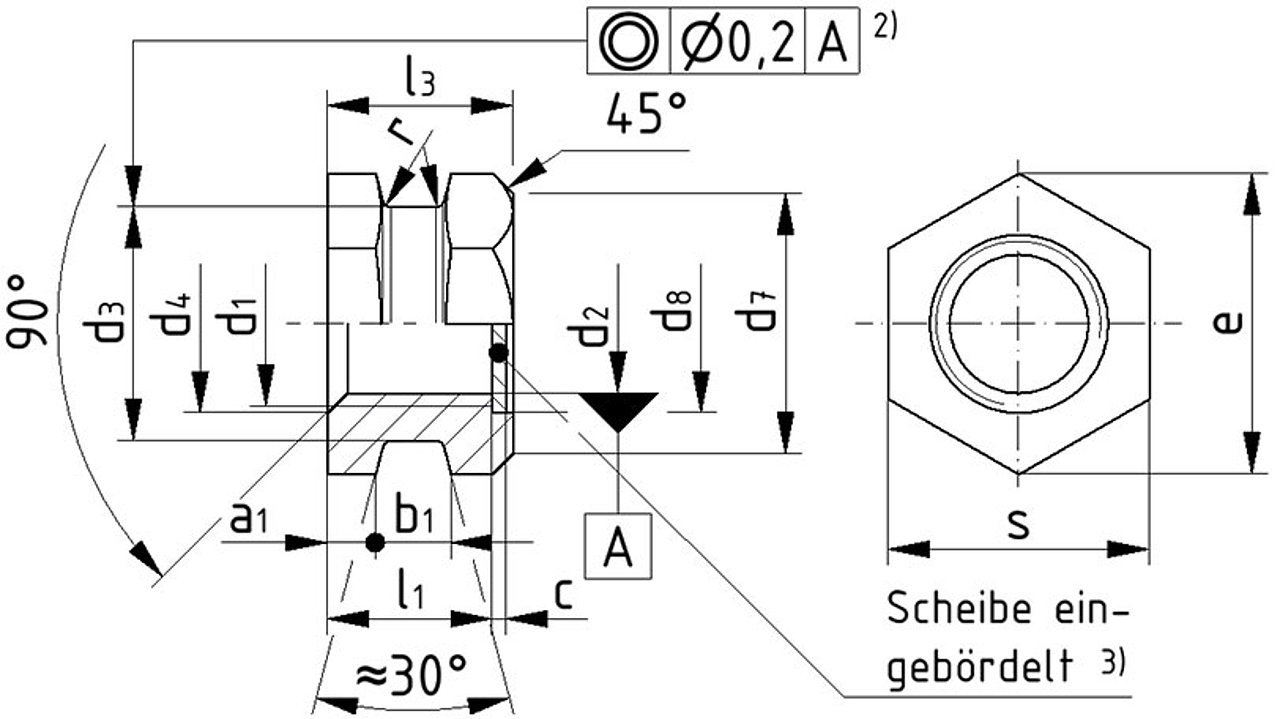

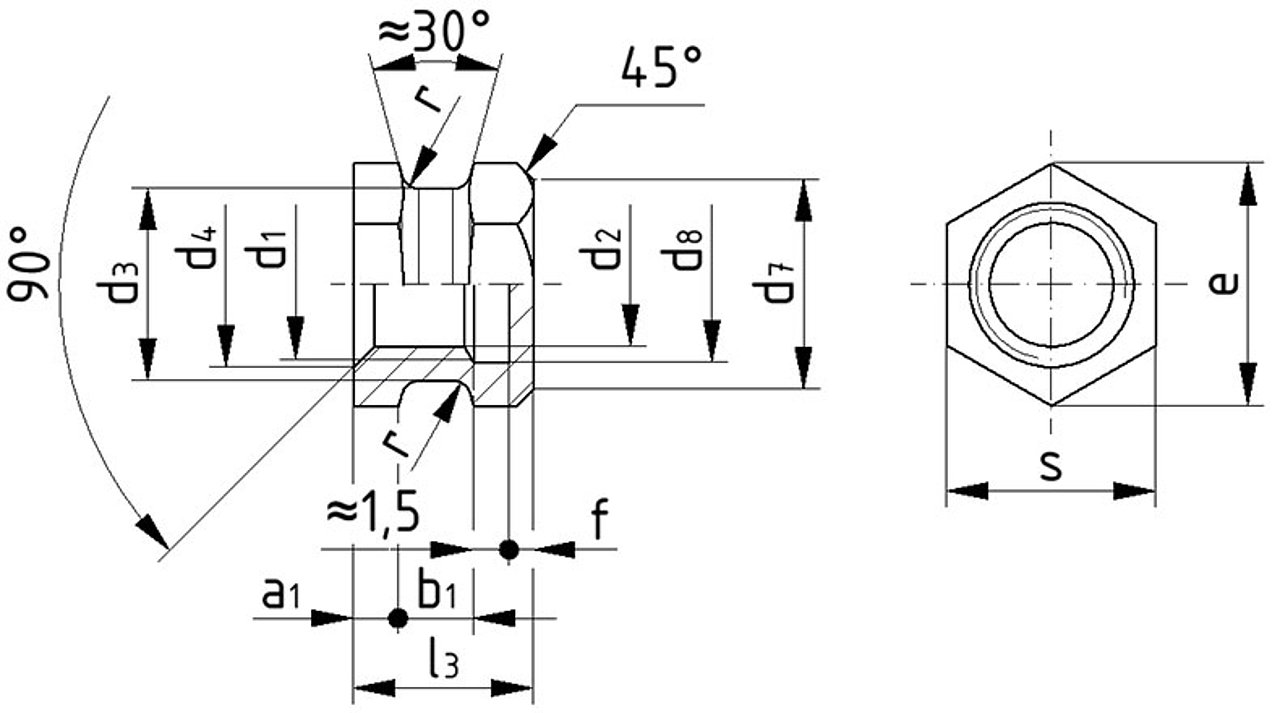

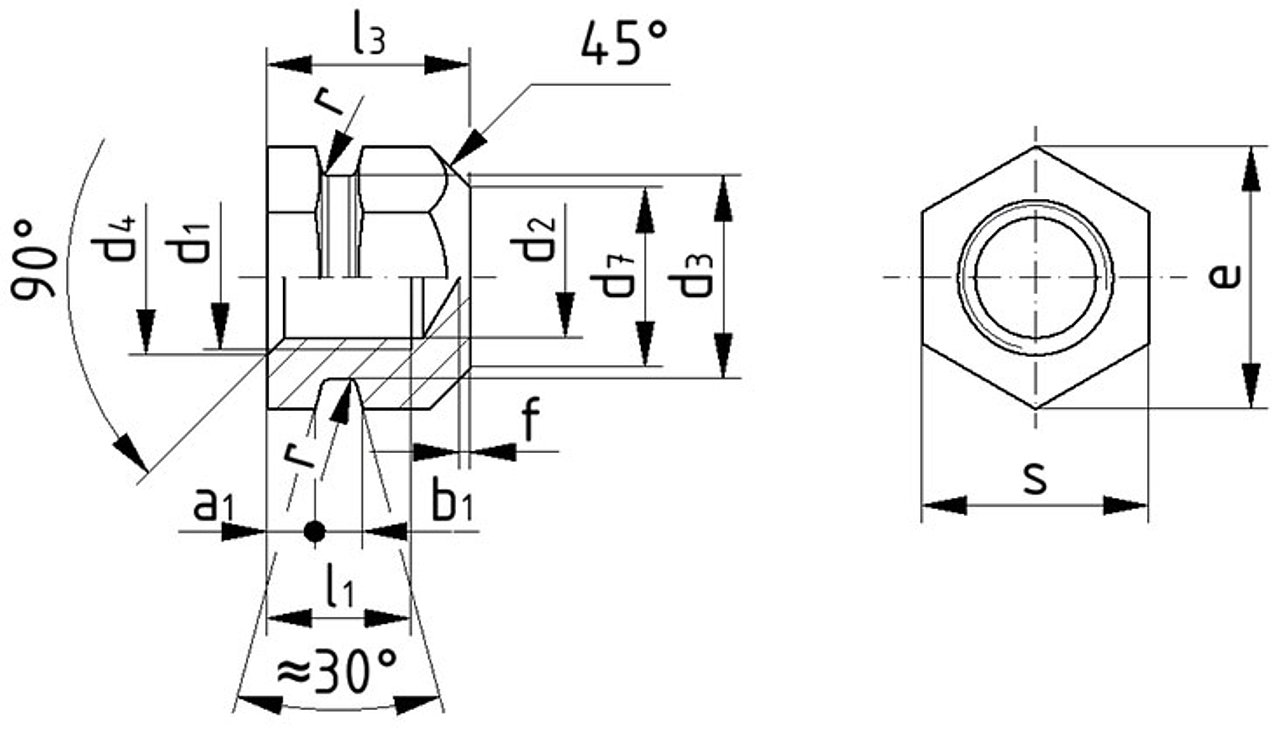

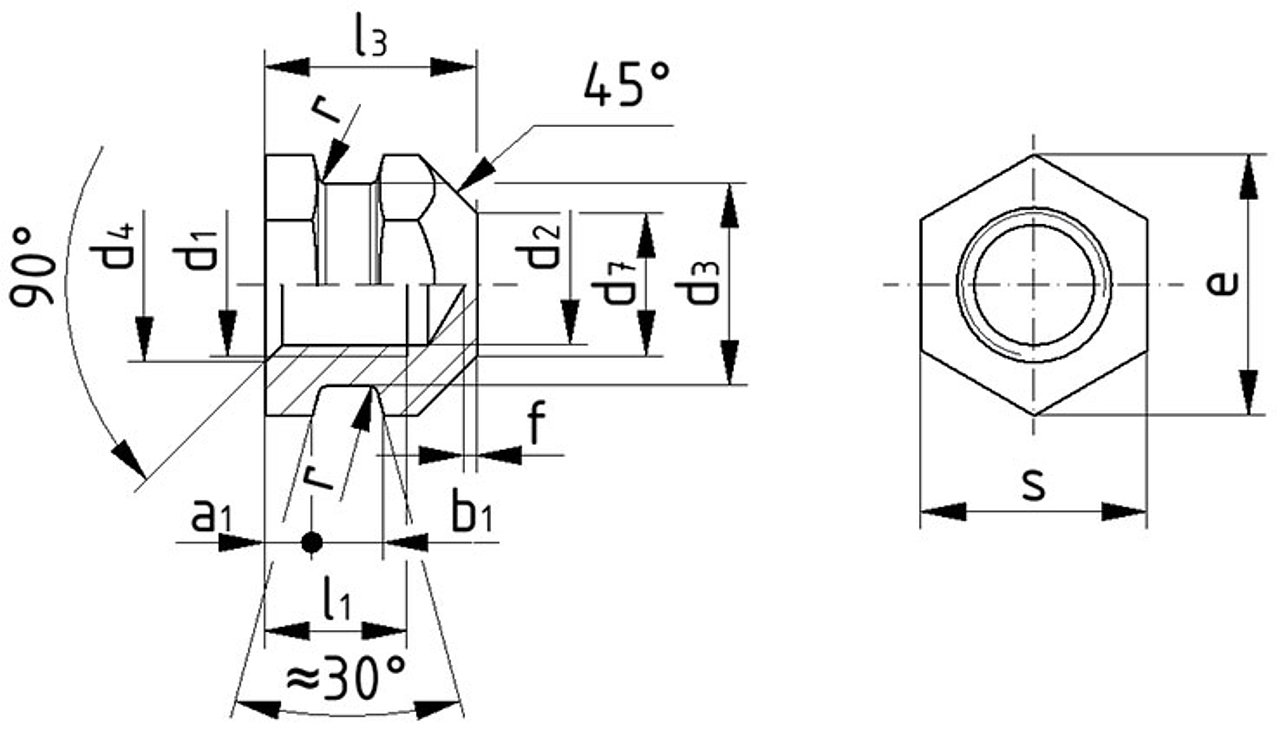

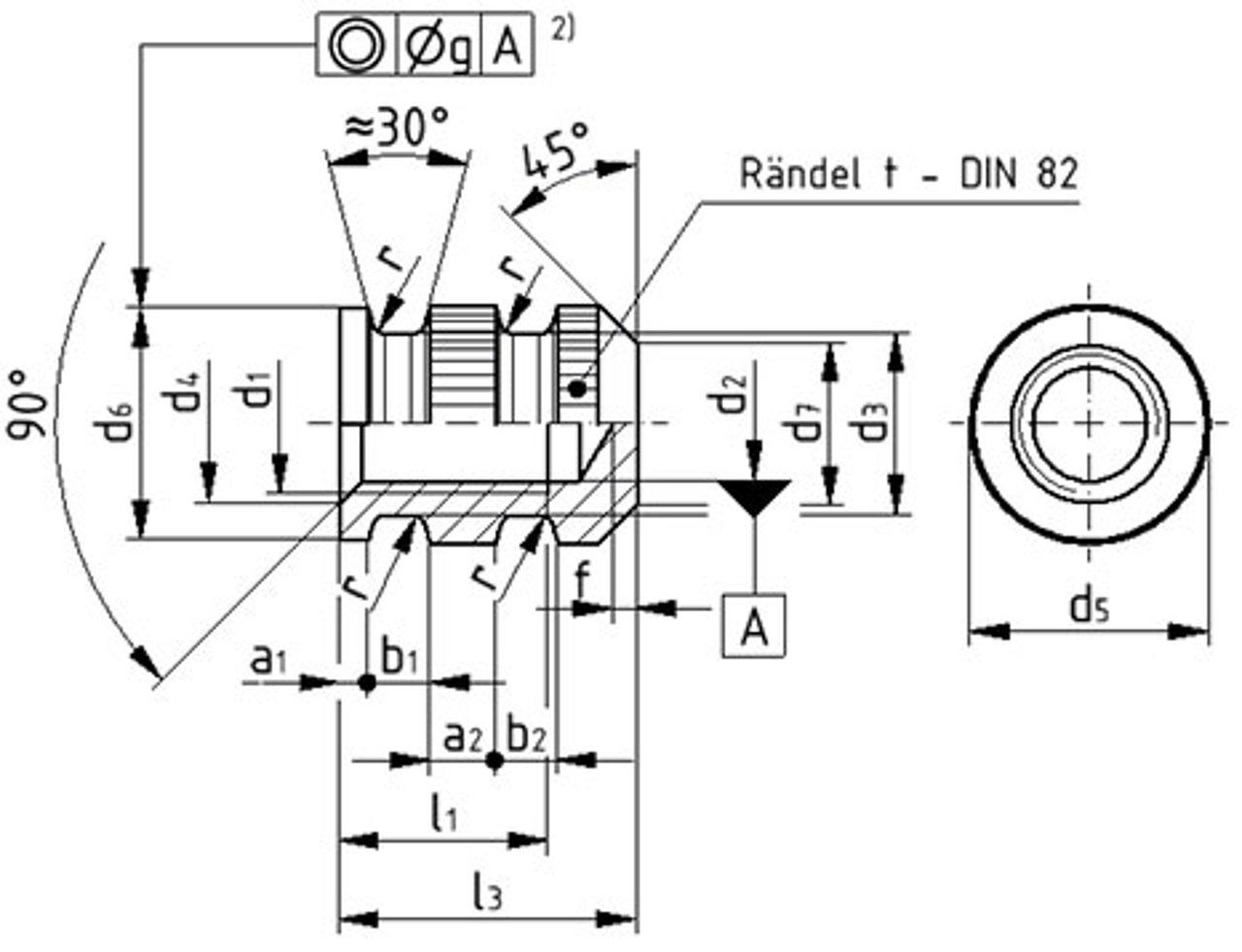

| Threaded bushings | |||||||||||

| Form | Tolerance | F / H | E / F / G / H | E / G | |||||||

| Thread d1 (6H) | M 2 | M 2.5 | M 3 | (M 3.5) | M 4 | M 5 | M 6 | M 8 | M 10 | M 12 | |

| a1 | 1 | 1 | 1.2 | 1.4 | 1.4 | 1.5 | 1.8 | 2.5 | 3 | 3.5 | |

| a2 | 1 | 1.2 | 1.2 | 1.5 | 1.5 | 2 | 2.5 | 3.5 | 4 | 5 | |

| b1 | 1.2 | 1.5 | 1.5 | 1.8 | 2.2 | 2.5 | 3.2 | 3.8 | 4.5 | 5.5 | |

| b2 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| b3 | 1.5 | 1.6 | 1.8 | 2.2 | 2.5 | 3 | 3.5 | 4.5 | 6 | 7 | |

| c | 0.32 | 0.32 | 0.32 | 0.54) | 0.54) | 0.54) | 0.54) | 15) | 15) | 15) | |

| d2 | H11 | 1.6 | 2.05 | 2.5 | 2.9 | 3.3 | 4.2 | 5 | 6.8 | 8.5 | 10.3 |

| d3 | h12 | 3.2 | 3.4 | 3.8 | 4.5 | 5 | 6.4 | 7.4 | 10.4 | 13 | 17 |

| d4 | 2.7 | 3 | 3.4 | 4 | 4.5 | 5.5 | 6.8 | 8.8 | 11 | 13 | |

| d51) | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | 124) | 154) | 184) | |

| d6 | h11 | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | 10 | 12.5 | 16 |

| d7 | - | - | 4.2 | 5.5 | 6 | 7 | 9 | 11 | 14 | 19 | |

| d83) | D11 | 2.6 | 2.8 | 3.2 | 3.8 | 4.5 | 6 | 7 | 9 | 11 | 13 |

| e | ≈ | - | - | 5.8 | 6.1 | 6.9 | 8.1 | 10.4 | 12.7 | 16.2 | 21.9 |

| g | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.16 | 0.16 | 0.2 | 0.2 | |

| l1 | h14 | 2.3 | 2.6 | 3 | 3.5 | 4 | 5 | 6 | 8 | 10 | 12 |

| l2 | h12 | 3.5 | 4 | 4.5 | 5.5 | 6 | 7.5 | 9 | 12 | 15 | 18 |

| l3 | h12 | 3.1 | 3.4 | 3.8 | 4.5 | 5 | 6 | 7 | 9.5 | 11.5 | 13.5 |

| l4 | h12 | 4.3 | 4.8 | 5.3 | 6.5 | 7 | 8.5 | 10 | 13.5 | 16.5 | 19.5 |

| r | ≈ | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| s | - | - | 5 | 5.5 | 6 | 7 | 9 | 11 | 14 | 19 | |

| t | ≈ | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | - | - | - |

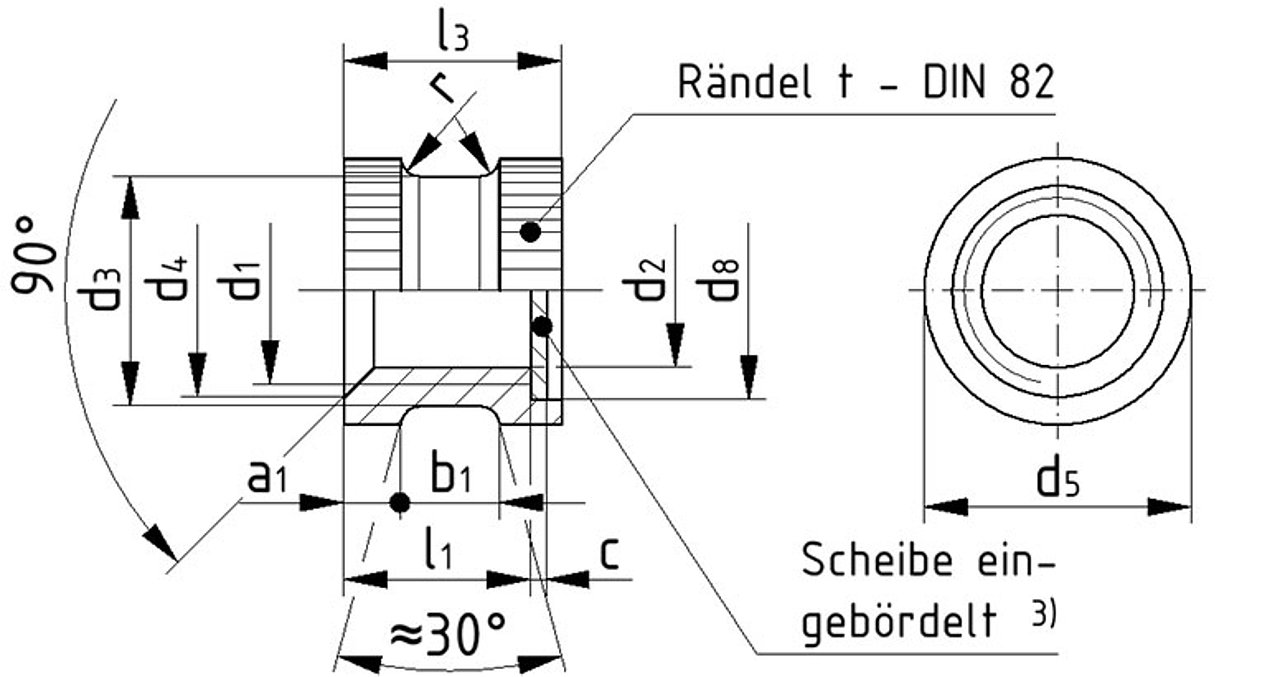

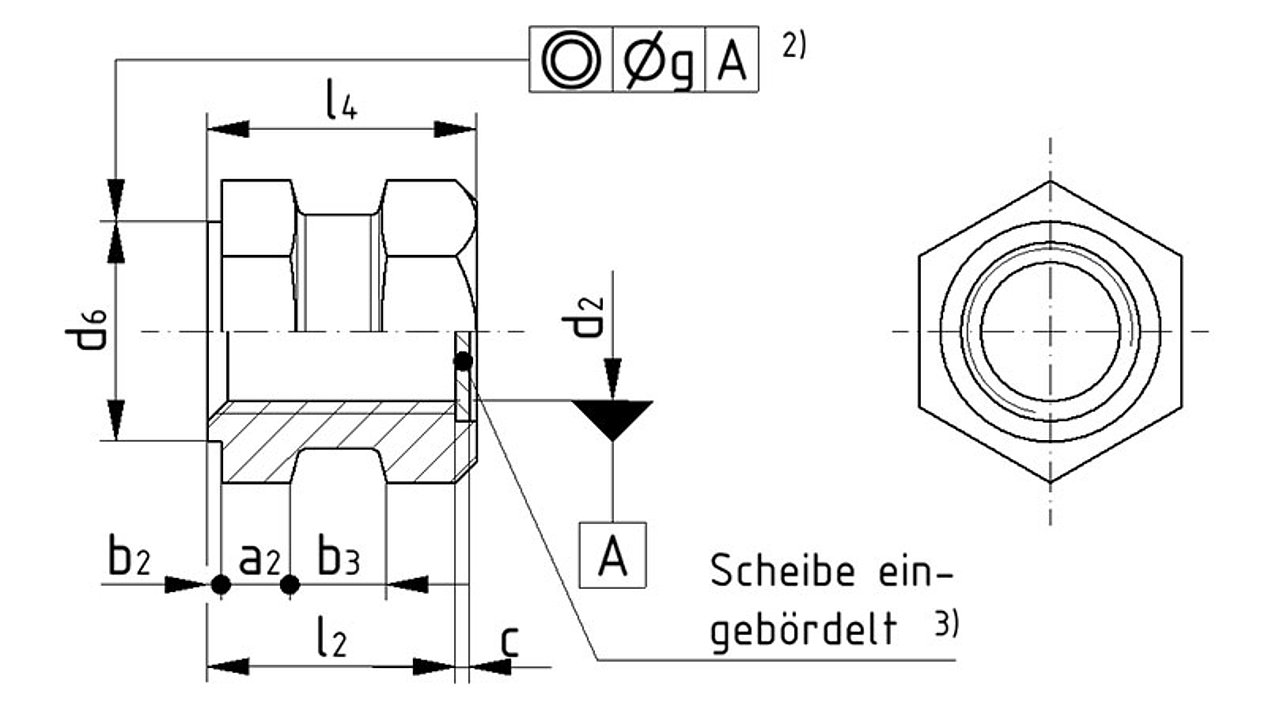

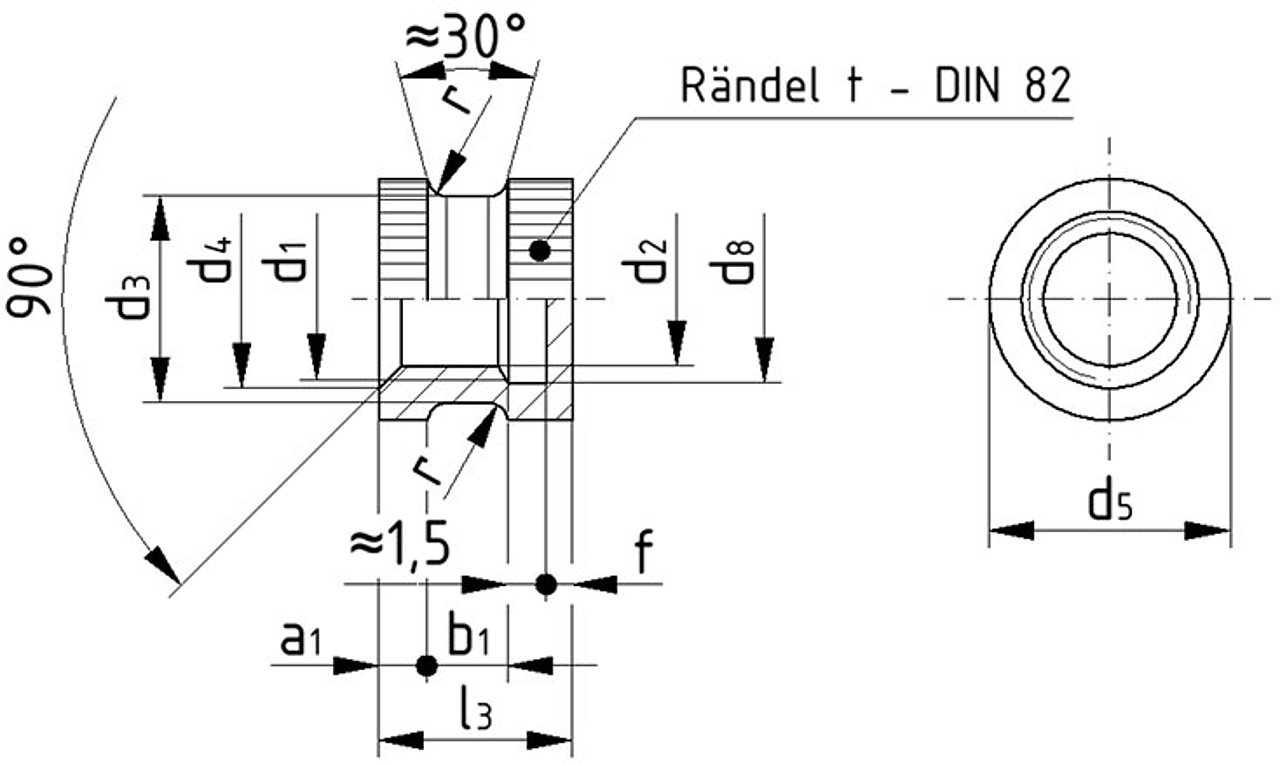

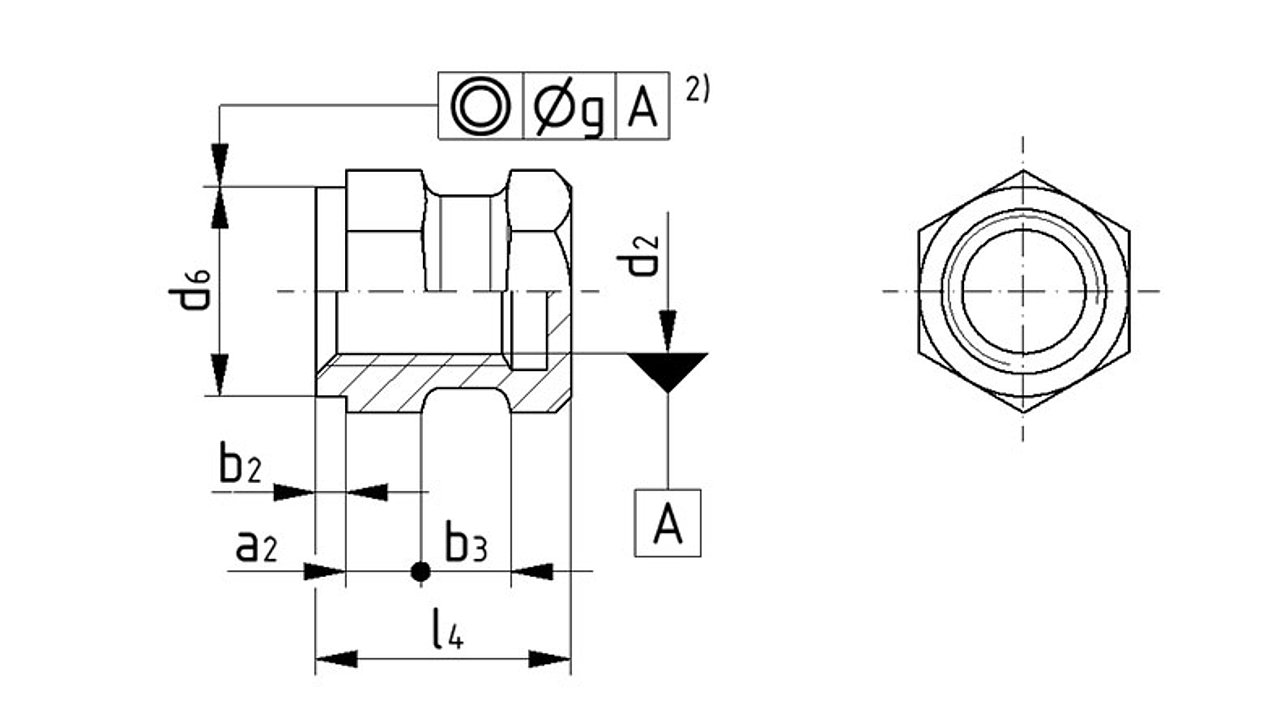

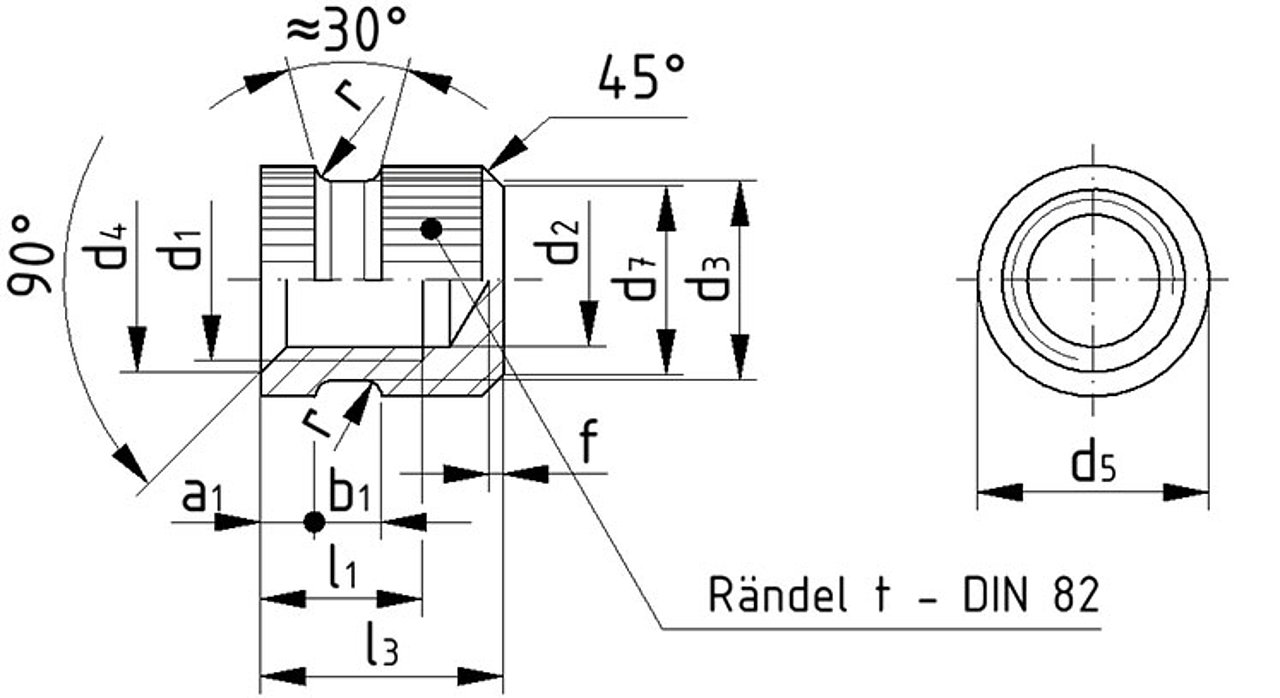

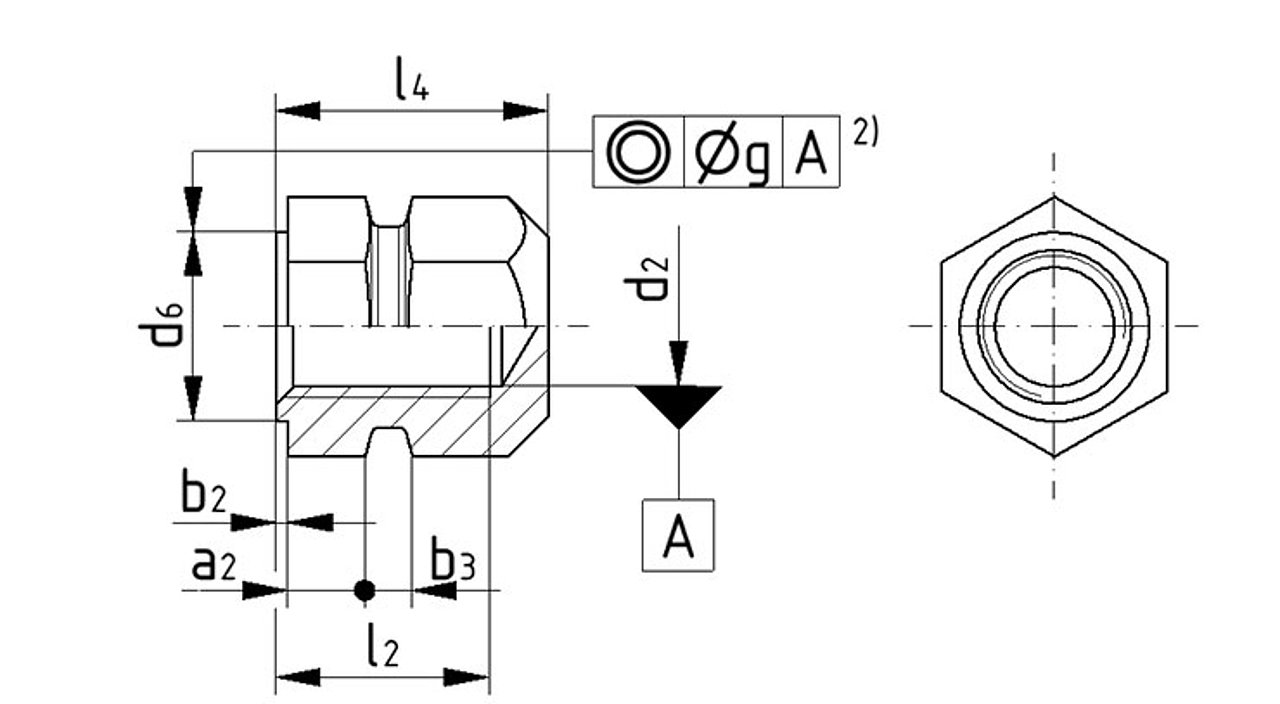

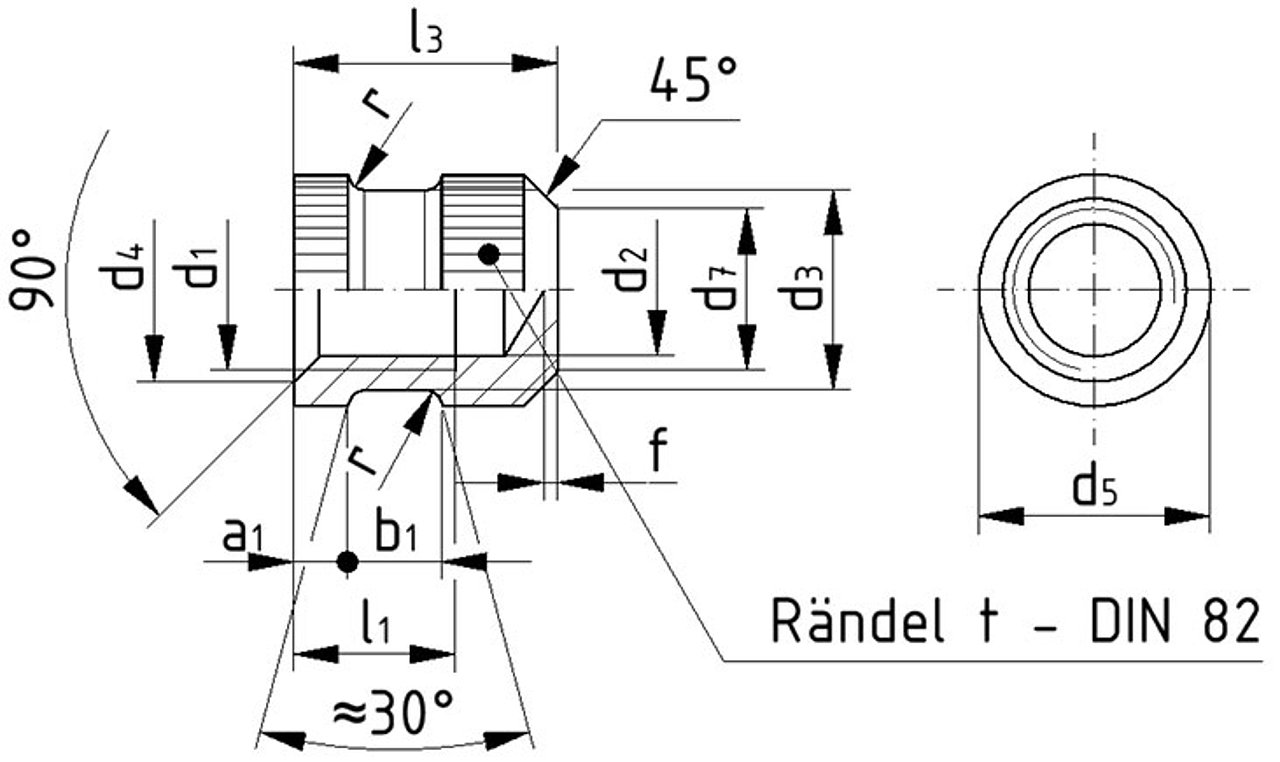

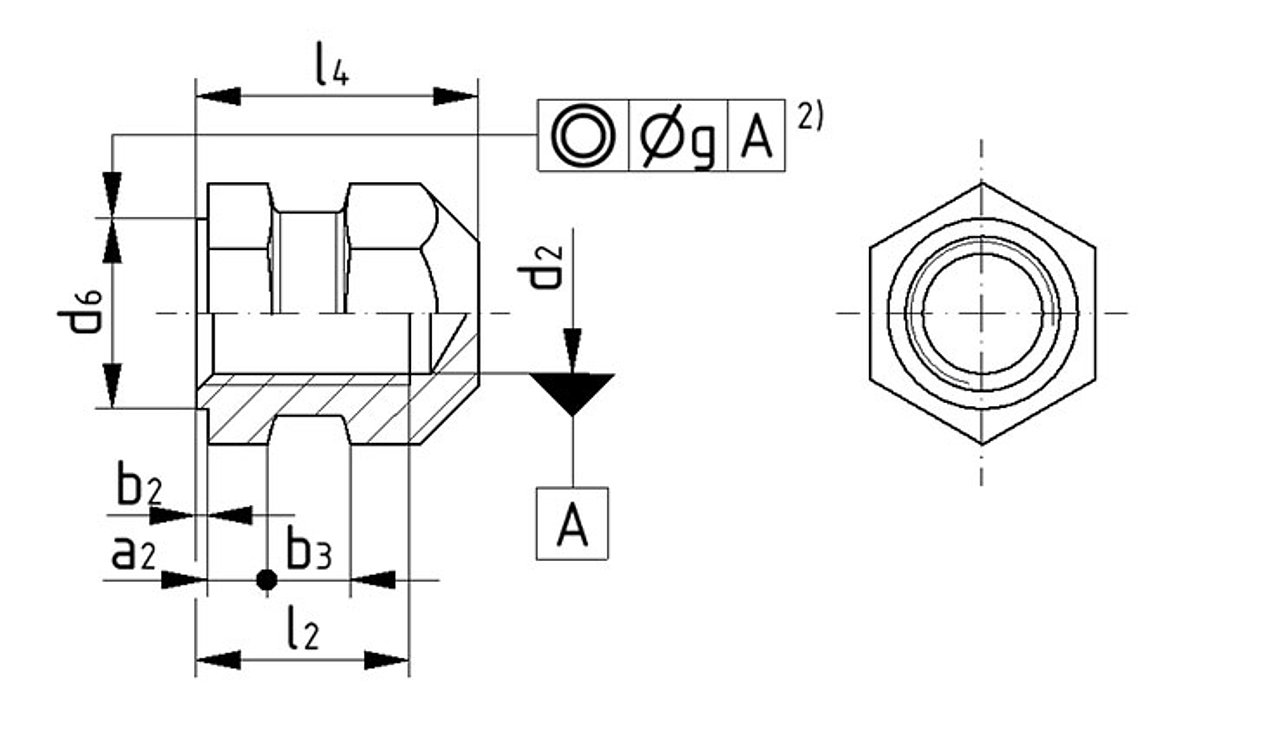

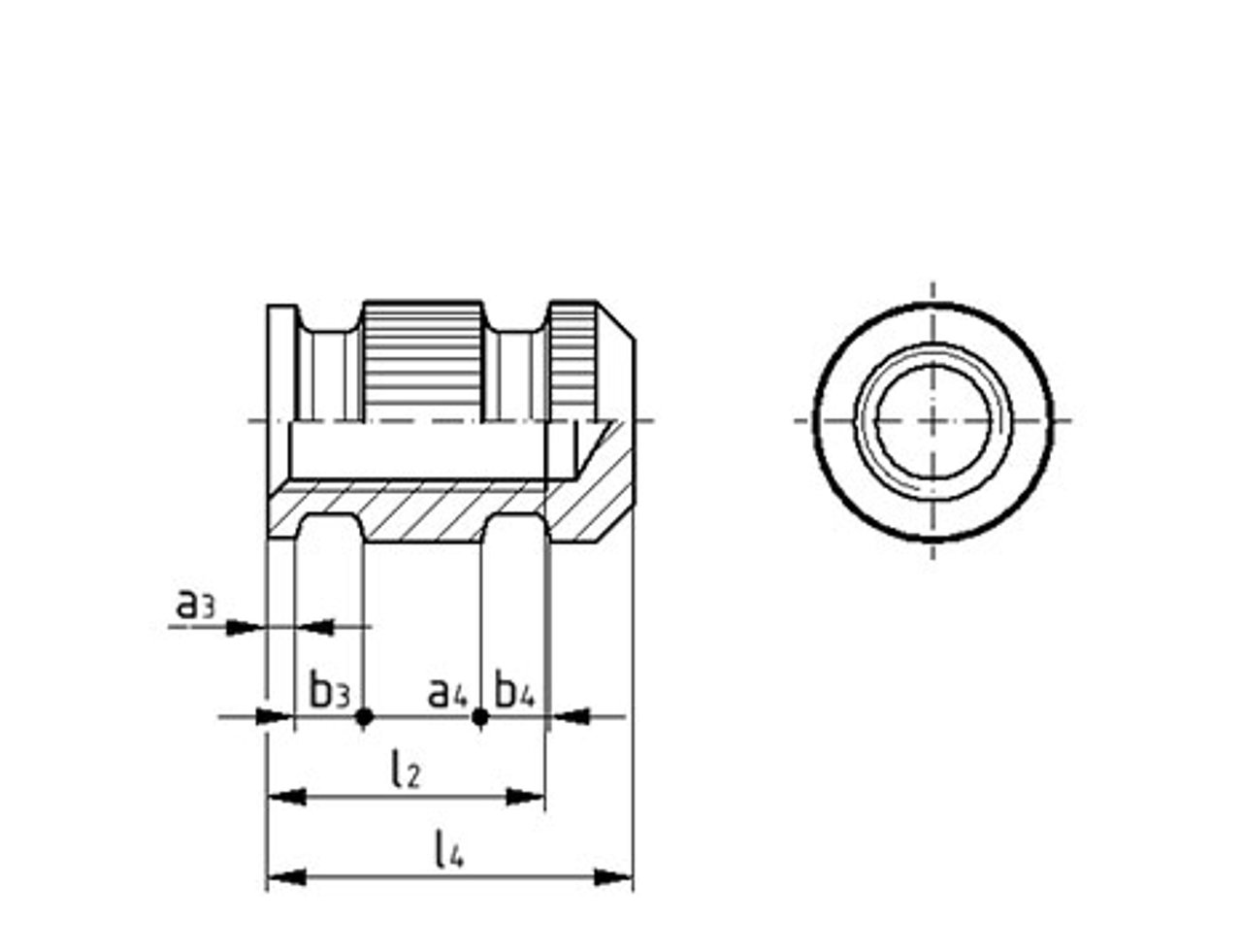

1) d5 = diameter of the semi-finished product (before it is knurled)

2) Coaxiality tolerance according to DIN ISO 1101

4) Recommendation of Linn Präzision

3) For the outer diameter of the disk: Tolerance range d11

Characteristics without tolerance specifications according to DIN ISO 2768-mK // delivery conditions according to DIN 267

| Threaded bushings | |||||||||

| Form | Tolerance | E / F / G / H | E / G | ||||||

| Thread d1 (6H) | M 3 | (M 3.5) | M 4 | M 5 | M 6 | M 8 | M 10 | ||

| a1 | 1.2 | 1.4 | 1.4 | 1.5 | 1.8 | 2.5 | Possible upon inquiry | ||

| a2 | 1.2 | 1.5 | 1.5 | 2 | 2.5 | 3.5 | |||

| b1 | 1.5 | 1.8 | 2.2 | 2.5 | 3.2 | 3.8 | |||

| b2 | 1 | 1 | 1 | 1 | 1 | 1 | |||

| b3 | 1.8 | 2.2 | 2.5 | 3 | 3.5 | 4.5 | |||

| f | (Production-related min. gradient x 1.5 / must be clarified before ordering) | ||||||||

| d2 | H11 | 2.5 | 2.9 | 3.3 | 4.2 | 5 | 6.8 | ||

| d3 | h12 | 3.8 | 4.5 | 5 | 6.4 | 7.4 | 10.4 | ||

| d4 | 3.4 | 4 | 4.5 | 5.5 | 6.8 | 8.8 | |||

| d51) | 4.2 | 5 | 5.5 | 7 | 8 | 12 | |||

| d6 | h11 | 4.2 | 5 | 5.5 | 7 | 8 | 10 | ||

| d7 | 4.2 | 5.5 | 6 | 7 | 9 | 11 | |||

| d8 | + 0.3 | 3 | 3.5 | 4 | 5 | 6 | 8 | ||

| g | h14 | 0.1 | 0.1 | 0.1 | 0.1 | 0.16 | 0.16 | ||

| l3 | h12 | 3.8 | 4.5 | 5 | 6 | 7 | 9.5 | ||

| l4 | h12 | 5.3 | 6.5 | 7 | 8.5 | 10 | 13.5 | ||

| r | 0.3 | 0.3 | 0.4 | 0.6 | 0.6 | 0.6 | |||

| t | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | - | |||

| s | 5 | 5.5 | 6 | 7 | 9 | 11 | |||

| e | 5.8 | 6.1 | 6.9 | 8.1 | 10.4 | 12.7 | |||

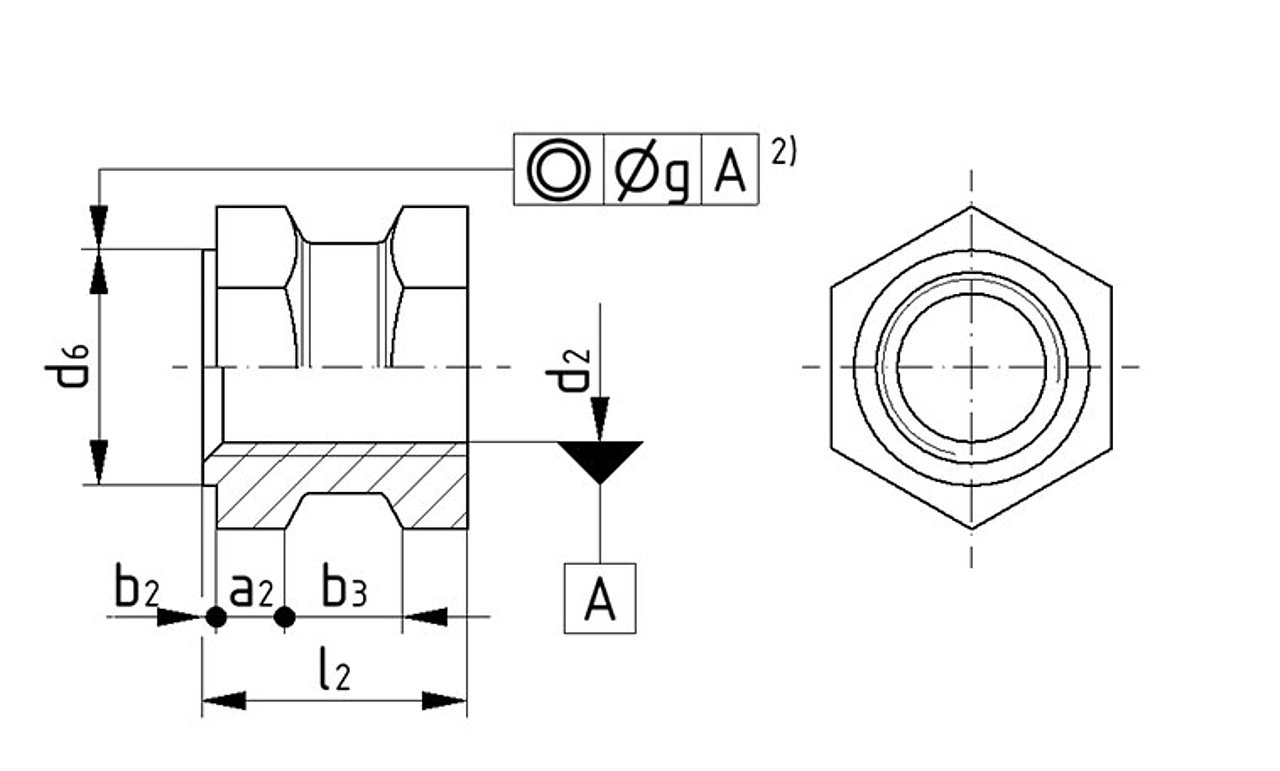

| Threaded bushings | |||||||||||

| Form | Tolerance | K / N | J / K / L / N | J / L | |||||||

| Thread d1 (6H) | M 24 | M 2.54 | M 3 | (M 3.5) | M 4 | M 5 | M 6 | M 8 | M 10 | M 12 | |

| a1 | 1 | 1.2 | 1.4 | 1.5 | 1.5 | 1.8 | 2 | 2.8 | 3.5 | 4 | |

| a2 | 1.2 | 1.5 | 1.6 | 2 | 2 | 2.5 | 3 | 4.2 | 5.5 | 6.5 | |

| b1 | 1.2 | 1.2 | 1.2 | 1.5 | 1.8 | 2 | 2.5 | 3 | 3.5 | 4 | |

| b2 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| b3 | 1.2 | 1.2 | 1.2 | 1.5 | 1.8 | 2 | 2.5 | 3 | 3.5 | 4 | |

| d23) | H11 | 1.6 | 2.05 | 2.5 | 2.9 | 3.3 | 4.2 | 5 | 6.8 | 8.5 | 10.3 |

| d3 | h12 | 3.2 | 3.4 | 3.8 | 4.5 | 5 | 6.4 | 7.4 | 10 | 13 | 17 |

| d4 | 2.7 | 3 | 3.4 | 4 | 4.5 | 5.5 | 6.8 | 8.8 | 11 | 13 | |

| d51) | ≈ | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | - | - | - |

| d6 | h11 | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | 10 | 12.5 | 16 |

| d7 | 3 | 3.4 | 3.8 | 4.5 | 5 | 6 | 7 | 9 | 12 | 15 | |

| f | + 0.24) | 0.4 | 0.4 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.8 | 0.8 | 1 |

| l1 | h144) | 2.3 | 2.6 | 3 | 3.5 | 4 | 5 | 6 | 8 | 10 | 12 |

| l2 | h144) | 3.5 | 4 | 4.5 | 5.5 | 6 | 7.5 | 9 | 12 | 15 | 18 |

| l3 | h124) | 3.8 | 4.2 | 4.8 | 5.5 | 6.5 | 7.6 | 9 | 12 | 14.2 | 17 |

| l4 | h124) | 5 | 5.6 | 6.3 | 7.5 | 8.5 | 10.2 | 12 | 16 | 19.2 | 23 |

| s | - | - | - | - | 6 | 7 | 9 | 11 | 14 | 19 | |

| e | ≈ | - | - | - | - | 6.9 | 8.1 | 10.4 | 12.7 | 16.2 | 21.9 |

| g 4) | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.16 | 0.16 | 0.2 | 0.2 | |

| r 4) | ≈ | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| t 4) | ≈ | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | - | - | - |

| Threaded bushings | |||||||||||

| Form | Tolerance | Q / S | P / Q / R / S | P / R | |||||||

| Thread d1 (6H) | M 2 | M 2.5 | M 3 | (M 3.5) | M 4 | M 5 | M 6 | M 8 | M 10 | M 12 | |

| a1 | 1 | 1.2 | 1.4 | 1.5 | 1.5 | 1.8 | 2 | 2.8 | 3.5 | 4 | |

| a2 | 1.2 | 1.5 | 1.6 | 2 | 2 | 2.5 | 3 | 4 | 5 | 5 | |

| b1 | 1.2 | 1.5 | 1.8 | 1.8 | 2.5 | 3 | 3.5 | 4.5 | 5 | 6 | |

| b2 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| b3 | 1.6 | 1.6 | 1.8 | 2 | 2.8 | 3.5 | 4 | 5.5 | 6 | 7 | |

| d2 | H11 | 1.6 | 2.05 | 2.5 | 2.9 | 3.3 | 4.2 | 5 | 6.8 | 8.5 | 10.3 |

| d3 | h12 | 3.2 | 3.4 | 3.8 | 4.5 | 5 | 6.4 | 7.4 | 10.4 | 13 | 17 |

| d4 | 2.7 | 3 | 3.4 | 4 | 4.5 | 5.5 | 6.8 | 8.8 | 11 | 13 | |

| d51) | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | - | - | - | |

| d6 | h11 | 3.5 | 3.8 | 4.2 | 5 | 5.5 | 7 | 8 | 10 | 12.5 | 16 |

| d7 | 2.5 | 2.5 | 2.8 | 3.5 | 4 | 5 | 6 | 7 | 10 | 12 | |

| f | + 0.2 | 0.4 | 0.4 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.8 | 0.8 | 1 |

| g | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.16 | 0.16 | 0.2 | 0.2 | |

| l1 | h14 | 2.3 | 2.6 | 3 | 3.5 | 4 | 5 | 6 | 8 | 10 | 12 |

| l2 | h14 | 3.5 | 4 | 4.5 | 5.5 | 6 | 7.5 | 9 | 12 | 15 | 18 |

| l3 | h12 | 4 | 4.6 | 5.5 | 6 | 7 | 8.3 | 9.8 | 12.6 | 15 | 17.8 |

| l4 | h12 | 5.2 | 6 | 7 | 8 | 9 | 10.8 | 12.8 | 16.6 | 20 | 23.8 |

| r | ≈ | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| t | ≈ | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | - | - | - |

| s | - | - | 5 | 5.5 | 6 | 7 | 9 | 11 | 14 | 19 | |

| e | - | - | 5.8 | 6.1 | 6.9 | 8.1 | 10.4 | 12.7 | 16.2 | 21.9 | |

| Threaded bushings | |||||||||||

| Form | Tolerance | T | T / U | U | |||||||

| Thread d1 (6H) | M 2 | M 2.5 | M 3 | (M 3.5) | M 4 | M 5 | M 6 | M 8 | M 10 | M 12 | |

| a1 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1.2 | - | - | - | |

| a2 | 1 | 1.1 | 1.3 | 1.6 | 1.8 | 2.2 | 2.8 | - | - | - | |

| a3 | - | - | - | - | 1 | 1 | 1.2 | 1.5 | 1.5 | 2 | |

| a4 | - | - | - | - | 4 | 4.5 | 5 | 6 | 8 | 10 | |

| b1 | 1.2 | 1.4 | 1.5 | 1.7 | 1.9 | 2.2 | 2.7 | - | - | - | |

| b2 | 1.2 | 1.4 | 1.5 | 1.7 | 1.9 | 2.2 | 2.7 | - | - | - | |

| b3 | - | - | - | - | 2 | 2.5 | 3 | 4 | 5 | 6 | |

| b4 | - | - | - | - | 2 | 2.5 | 3 | 4 | 5 | 6 | |

| d2 | H11 | 1.6 | 2.05 | 2.5 | 2.9 | 3.3 | 4.2 | 5 | 6.8 | 8.5 | 10.3 |

| d3 | h12 | 3.2 | 3.5 | 4 | 4.6 | 5.3 | 6.6 | 7.8 | 10.5 | 13 | 15.7 |

| d4 | 2.7 | 3 | 3.4 | 4 | 4.5 | 5.5 | 6.8 | 8.8 | 11 | 13 | |

| d51) | 4.5 | 5 | 5.5 | 6 | 7 | 9 | 10 | 12 | 15 | 18 | |

| d6 | h11 | 4.5 | 5 | 5.5 | 6 | 7 | 9 | 10 | 12 | 15 | 18 |

| d7 | 3.4 | 3.6 | 3.8 | 4.5 | 5 | 6 | 7 | 9 | 12 | 15 | |

| f | +0.2 | 0.4 | 0.4 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.8 | 0.8 | 1 |

| l1 | h14 | 3.5 | 4 | 4.5 | 5.5 | 6 | 7.5 | 9 | - | - | - |

| l2 | h14 | - | - | - | - | 8 | 10 | 12 | 16 | 20 | 24 |

| l3 | h12 | 5.2 | 6 | 7 | 8 | 9 | 10.5 | 12.8 | - | - | - |

| l4 | - | - | - | - | 11 | 13.3 | 15.8 | 20.6 | 25 | 29.8 | |

| g | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.16 | 0.16 | 0.2 | 0.2 | |

| t | ≈ | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | 0.8 |

| r | ≈ | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |